As technology and industrial processes evolve, companies increasingly rely on SCADA (supervisory control and data acquisition) systems to support high-level applications. System functionality has increased as a result, making the inclusion of SCADA more critical than ever. This has accelerated system obsolescence and shortened the useful lifespan for legacy systems.

SCADA is a universally used system architecture found in modern-day industrial facilities worldwide. Composed of computers, networked data communications, hardware, and software components, SCADA provides industries with real-time data acquisition and high-level supervisory management and processing power. SCADA compiles and delivers information about your facility’s production processes to a central hub; the system then transmits digitized data in real-time while compiling backlogs for easy future analysis.

SCADA is widely used in the following industries across America:

- Oil and Gas

- SAGD

- Petro-Chemical

- Oilsands

- Agricultural

- Refining

- Aggregates

- Power and Energy

- Water and Wastewater Treatment

Read more about the importance of SCADA: What is SCADA, and Where is it Used?

Even facilities that already use SCADA may face a time when migration is necessary. There are various reasons for this; during an asset purchase, the purchaser might need to migrate the existing SCADA system into the new one. Smaller companies that use web-hosted SCADA often want to move to their own client-owned system.

Whatever the reason, collecting the following information is critical to a successful migration and will make things easier for you.

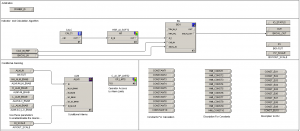

Preparing for SCADA Migration

- What is the connectivity of the servers in question? Is your server solely collecting data, or is it already connected to your business systems?

- What data is required on the field level (reporting systems, production accounting systems)? Field instrumentation is an essential component of data collection and comes in various forms, including proximity sensors, machine vision systems, temperature and pressure sensors, and energy monitors.

- What data is required for your facility headquarters? This information pertains to production operations, engineers, plant managers etc.

- Is your hardware up-to-date, or is it obsolete and unserviceable? If your system is outdated, strategic planning and upgrades can bring your SCADA up to speed. As technology development accelerates, your system must keep up if you want to stay competitive in your industry.

- Is your hardware open source, or is it proprietary to the hardware used?

- Do you have a complete list of all the sites requiring migration?

- Do you have access to the login information to access the system?

- Do you have trouble with connectivity in the area? This may require a communications upgrade during the migration.

- Are you using an integration company (Crossroad) or in-house experts? What is their level of experience?

- Can any of your sites benefit from using MQTT (message queueing telemetry transport) SpB to lower bandwidth and increase data resolution? MQTT interfaces expand the reach of machine data, giving end-users more options and making direct cloud integration possible. If you need frequent communication for site measurements, you might have to shut down your SCADA to get bandwidth. Integrating MQTT SpB can prevent costly downtime and increase the efficiency of your system.

Completing a Successful SCADA Migration

SCADA migration doesn’t need to be difficult with the right information and approach. Crossroad Energy Solutions automation specialists have the advanced skills and experience to implement automated control systems. Whether you require troubleshooting of your current system, remote support, migration, or a complete upgrade of your SCADA, we have a diverse team of technicians to assist you throughout Canada and the USA. We also offer 24/7 emergency callout support.

We invite you to click here or to call us about your facility’s needs at 877-872-0222.