It’s Time To Focus On Heat Trace!

October 28, 2021

Electrical Maintenance – Industrial Heaters

November 15, 2021Infrared scanning is incredibly useful for identifying potential problems with your electrical equipment. For preventative maintenance of your electrical equipment, infrared scanning is a critical step that shouldn’t be overlooked!

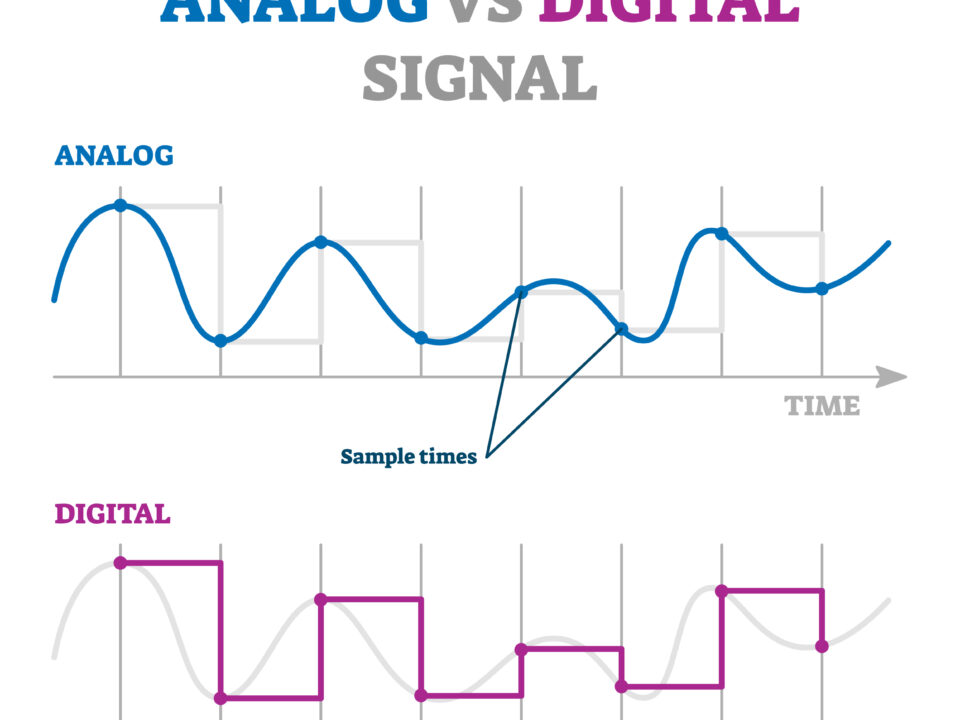

Thermal imaging cameras detect radiation in the infrared electromagnetic spectrum. In other words, these cameras detect the thermal energy (heat) emitted from the area that is being scanned and project it onto a screen overlayed with the actual image. This technology allows the technicians to find hotspots and large temperature differentials.

How Infrared Scanning Works

Why is this useful with electrical equipment? Most electrical components use what are known as “contacts” to make electrical connections. “Contacts” are pieces of conductive material that are mechanically brought together to close a circuit and separated to open the circuit. These contacts are subject to wear and tear and will eventually start to break down, which can cause arcing and a bad connection. This is one of the leading causes of hot spots and, ultimately, fires. Infrared cameras pick up these hot spots long before the naked human eye (or nose) will be able to identify the extra heat from an arcing contact.

Your switchgear is a great candidate to be thermally scanned. Many switchgear manufactures now have thermal viewing ports built into the covers to allow thermal scanning without exposing the technician to the risk of arc flash.

Benefits of Using Infrared Scanning

In addition to switchgear, thermal scanning can help identify potential problems with many components in your electrical system, including but not limited to:

- Motor windings – hot spots indicate damaged insulation, winding failures, short circuits, or insufficient grounding

- Cables – hot spots indicate an overload

- Fuses and breakers – hot spots indicate overload, bad connections, corroded contacts

- Bearings – hot spots indicate imminent failure

- Power distribution panels – hot spots indicate phase load imbalance, poorly installed breakers, faulty circuit breakers, undersized wiring, poor connections

- Control panels – contractor under-sizing, poor or defective connections, short circuits, and deteriorated insulation

Other Benefits:

- Increases general safety

- Reduces risk of fire

- Depending on your insurance provider, regular thermal scans can reduce your insurance premiums.

- Reduce potential downtime and system failures

- Helps with maintenance planning and resource allocation

- Scans are usually done on “live” equipment – no interruption to the system

Identifying hot spots doesn’t necessarily mean there is a problem. However, it allows for further investigation into an anomaly that is found during the scan. For this reason, electrical thermal scans are best performed by electricians who will be able to safely investigate what the underlying problem might be.

Crossroad Energy Solutions offers premium thermal scanning. Our technicians are certified to use thermal imaging scanners on electrical equipment and are specifically trained to accurately assess what a hot spot or temperature differential could indicate. All our thermal scanning technicians are also electricians. They will find the potential problem, safely investigate the cause, offer a solution, and perform the job.

We offer this service in and around the following areas:

Shaunavon, Saskatchewan

Kindersley, Saskatchewan

Slave Lake, Alberta

Edmonton, Alberta

Drayton Valley, Alberta

Sylvan Lake, Alberta

Calgary, Alberta

Claresholm, Alberta

Medicine Hat, Alberta

Give us a call to book a Thermal Scan at your facility at 1-877-822-0222.