A look At CSA, UL And ETL Certification

March 18, 2022

Why Work With Crossroad Energy Solutions Inc?

June 2, 2022If you sat down and intentionally tried to conjure up a series of events to cripple the global supply chain, you’d be hard pressed to do a better job than what’s happened organically over the past 2 years.

COVID-19 lockdowns and restrictions can be blamed for the bulk of the issues. Producers of basic components and raw materials faced labor shortages due to government work restrictions. Knock on effects of border-closures, restaurant-closures, and most indoor venue-closures, coupled with cash-subsidy programs left consumers with nowhere to be and money in their pockets.Consumer spending on goods, (especially E-Commerce) skyrocketed This increased the demand for goods (rather than services) which overwhelmed the shipping industry, one that was already feeling the effects of a reduced labor force.

Throw in a fire at a massive semi-conductor plant in Japan, a huge container ship blocking the Suez Canal for a week, floods in Western Canada rendering its Pacific shipping ports useless (creating huge wait times at Californian shipping ports), Canadian blockades and skyrocketing fuel costs, and you’ve got a perfect storm for a crippled North American supply chain.

As a company that relies on installing products for its customers, we are facing tremendous challenges trying to source material in a timely fashion.

We’re seeing unprecedented wait times on nearly all electrical and instrumentation products including:

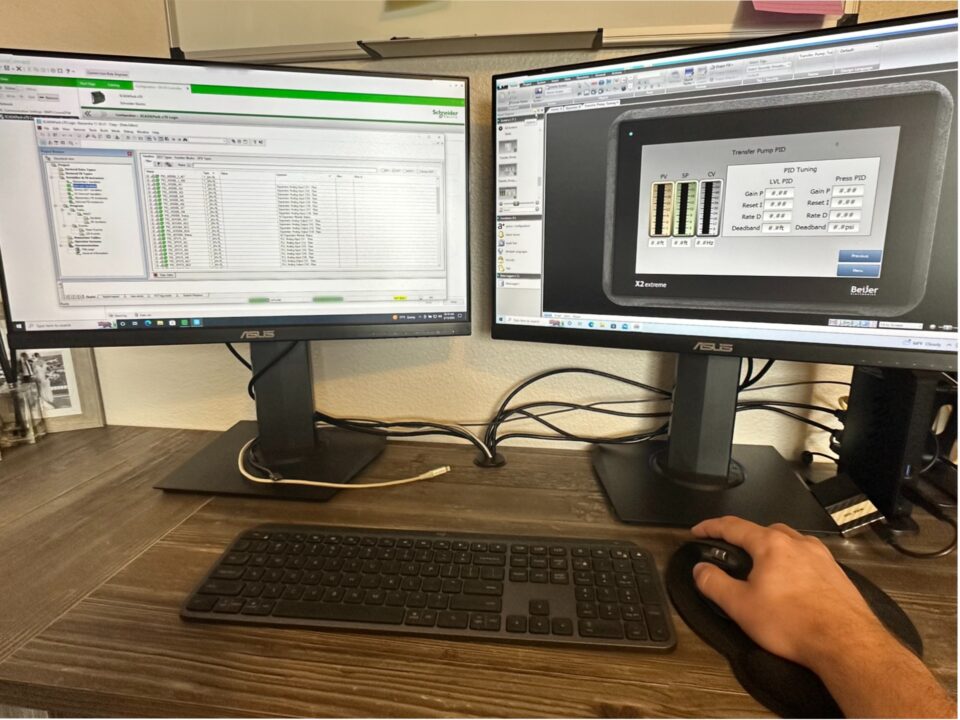

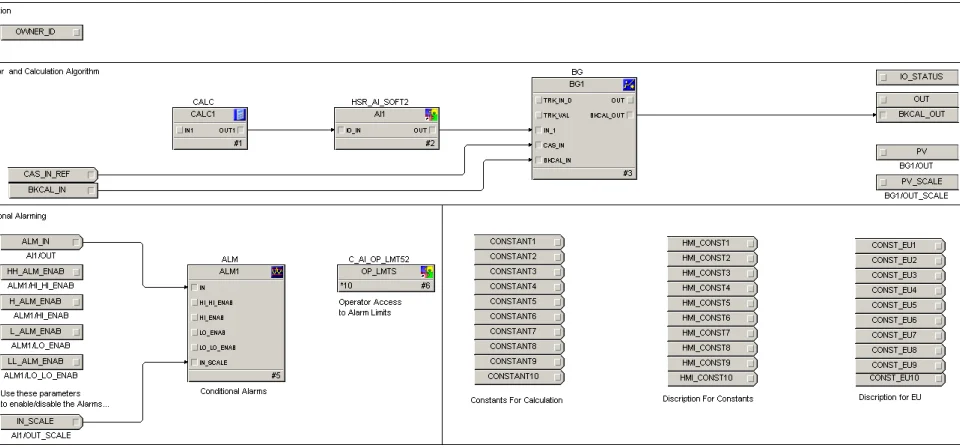

PLC controllers

PLC input cards

PLC output cards

HMIs

Relays

Grounding bars

Cables

Junction boxes (all sizes)

Breakers

Pushbuttons

Lights

Variable frequency drives

Terminal blocks

A Few Tips to our Customers to try to Avoid Downtime

1. Get Your Orders in as Soon as Possible!

If you know you have a PLC upgrade coming down the pipe, get on it now. The longer you wait, the worse it’s going to be. We’re seeing 6–8-month lead times on many PLC components from various manufactures. We’re not kidding – these wait-times are serious!

At the very least, get the long-lead items on the way and come up with a plan to source the “B-material” later.

2. Be Open to Using Different Manufactures

Similar products of the same quality and function are usually available from a variety of manufacturers. Being stuck on one manufacturer will limit your ability to figure out a solution to long lead-times.

3. Engage Us Early

If you’re designing something, reach out to someone at Crossroad Energy Solutions and let us talk to our vendors and get a sense of what the lead times are on the products you’re considering.