What Are Industrial Control Panels?

January 7, 2022

Control Panel ETL Certification

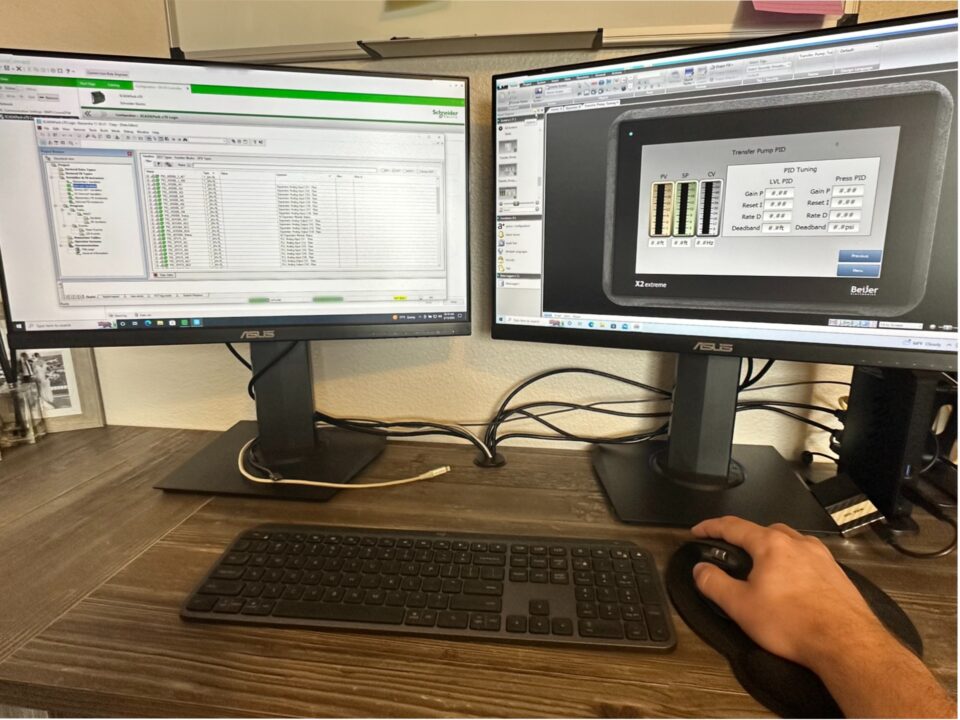

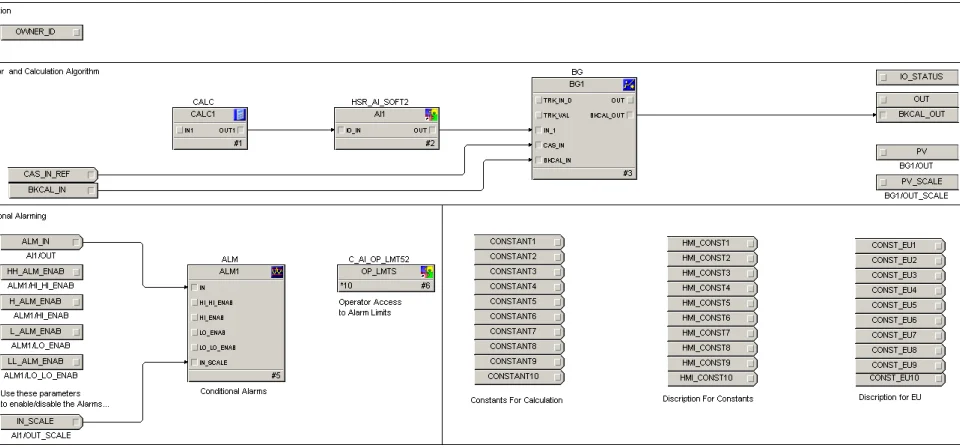

January 21, 2022Industrial Controller (RTU/PLC): Think of this as the “brains” of the operation.

Many control panels will have an industrial controller installed to monitor and control the facility’s processes as intended. In this case, we used the SCADA Pack 357 RTU. However, there is a wide variety of RTU’s and PLC’s available depending on the application. Crossroad Energy Solutions can help you determine which controller will best suit your situation.

Label/Tag on Each Wire Termination: Identification tags applied to every termination help future maintenance electricians determine the route and identity of each wire/connection more quickly. This dramatically reduces maintenance and troubleshooting costs.

Circuit Breaker: Automatically cuts power to all components downstream of the devices if an overcurrent occurs, protecting the devices and personnel downstream of the breaker. Breakers can also be used to shut down power to the panel manually.

Identifying Label & Holder: Identifies wire location and references control panel drawing.

Spiral Wrap: Plastic wire wrap that mechanically protects the wire from getting caught in the door and other components.

Uninterruptible Power Supply (UPS): Provides emergency power to the control panel if the primary power source unexpectedly shuts down.

Battery Backup: This battery provides power to the UPS in case of an unexpected power failure.

Power Supply: This unit supplies the required power to the components in the control panel by switching from 120VAC to 24VDC.

Ethernet Switch: This device allows the components within the control panel to communicate with each other via a Cat5 or Cat6 cable and using a standard “language” or “protocol.”

Wire Duct: Used to organize and route wires from one component to another. The duct offers a level of protection to the wire and the electricians working on the panel.

Relays: Mechanism used to remotely switch a circuit from open to closed or closed to open, depending on the situation.

Fused Terminal Blocks: It is a terminal block protected by a fuse. Terminal blocks are used to connect two wires for wire-to-wire connections.

Feed-Through Terminal Blocks: They are used to connect two wires for wire-to-wire connections.

Panel Enclosure / Junction Box: A cabinet that houses the electrical equipment. This enclosure protects people working around the equipment and protects the equipment inside the enclosure. Every enclosure is built to a particular protection standard or “NEMA” rating.

Double Stack Fused Feed-Through Terminals: Terminal block with two sections, the bottom section is a feed through, and the top section is fused. These terminal blocks were selected for space-saving-purpose. Terminal blocks are used to connect two wires for wire-to-wire connections.

Spare Fuse Holder: A convenient spot to keep spare fuses. The operators often fill the holder with the most common fuses in the panel to help avoid downtime.

Din Rail Mounted on Back-pan: Standardized metal mounting rail widely used for mounting control panel components to the back pan.

Ground Bar: A common path to ground to complete electrical circuits.