Obsolete PLC5 + SLC500 Migrations

July 12, 2021

The End Of Venting Of Pneumatic Devices

August 9, 2021Obsolete HMI Hardware, Software, And SCADA Systems Migrations

Running end-of-life systems introduces the risk of irrevocable damage and costly downtime in the event of a component failure. Outdated technologies are often no longer supported or manufactured, which leads to a lack of replacement parts. Even if you have access to these parts, servicing may be unavailable. This inconvenience results in frustrating and expensive downtime that could be detrimental to your operations and personnel.

Continue reading to learn why it is critical to understand the risk of operating obsolete HMI Hardware, Software, and SCADA systems and how you can proactively protect your organization.

HMI Hardware and Software Innovations

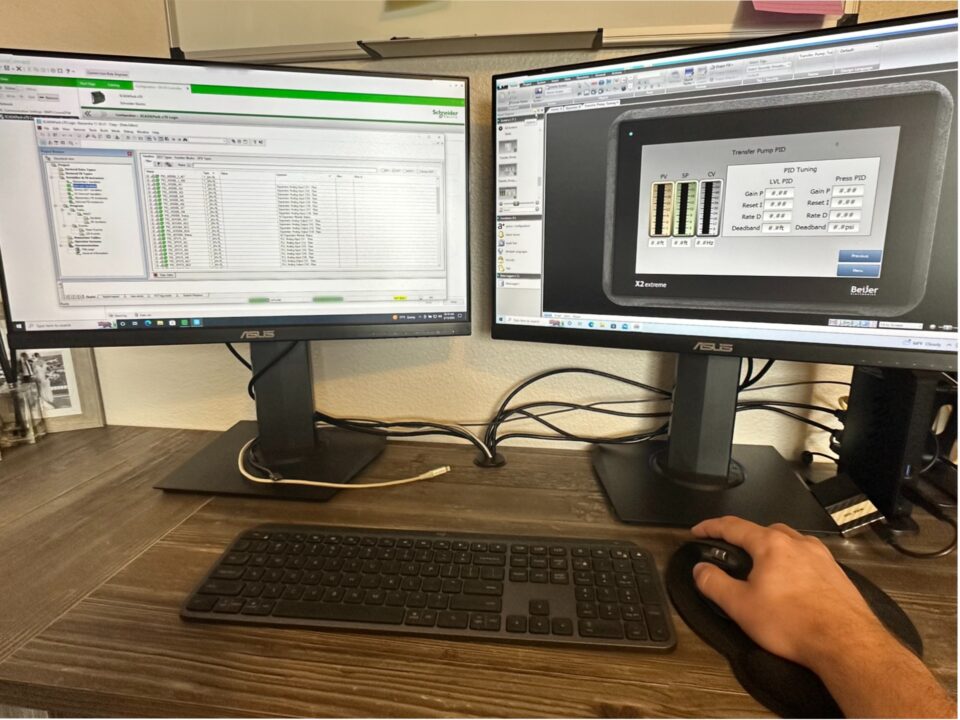

A Human-machine interface (HMI) is a component of a device or software application that enables a person to engage with a machine. These components can be as ubiquitous as single-touch display mounts and smartphones—or as technologically advanced as a multi-touch control panel on a plant floor. The term “HMI” can refer to any graphical display that allows a user to interact with a device, but HMI is commonly used when referring to industrial processes.

Industrial HMIs are robust interfaces capable of handling the demanding volume and complexity of plant-wide machinery. Like PLCs, however, they reach an end-of-life phase in which manufacturers no longer support them.

New advancements in responsive design interfaces continue to increase the value of HMI applications in the factory setting. Modern HMIs offer a myriad of improved capabilities, including:

- Cloud/web-based software vs. stand-alone with no connectivity. One hallmark of today’s digital age is the cloud. Cloud software enables companies to adapt, scale, and streamline operations at an increased speed and reduced cost. These intelligent and dynamic visualization systems empower users to build industrial applications that automatically respond to unique situations. Remote software allows users to view and interact with their operations screen from any computer or location. Years ago, you had no option for remote connectivity and had to be at the facility to view your operational data.

- Improved CPU power. Like the advancements in the personal computers and electronics we use daily, modern HMIs provide improved graphics, larger screens, better trending, and higher processing power.

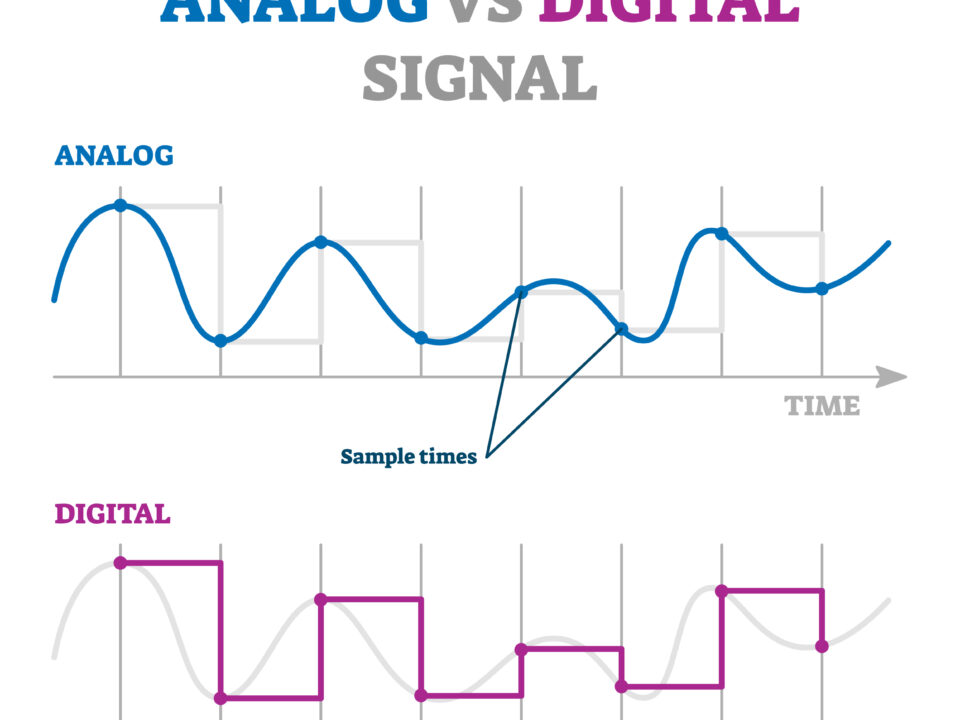

- Expansion of communication protocol. HMIs were often built to specific protocols, which limited the number of devices they could communicate with. Thanks to technological evolution, HMIs now communicate with and connect to many different protocols, users, and devices.

- Improved trending. Older devices often lacked the capacity of the feature-rich flexibility that we find in modern HMIs. New HMIs have the horsepower to create custom trends, export data to excel, and build better graphics.

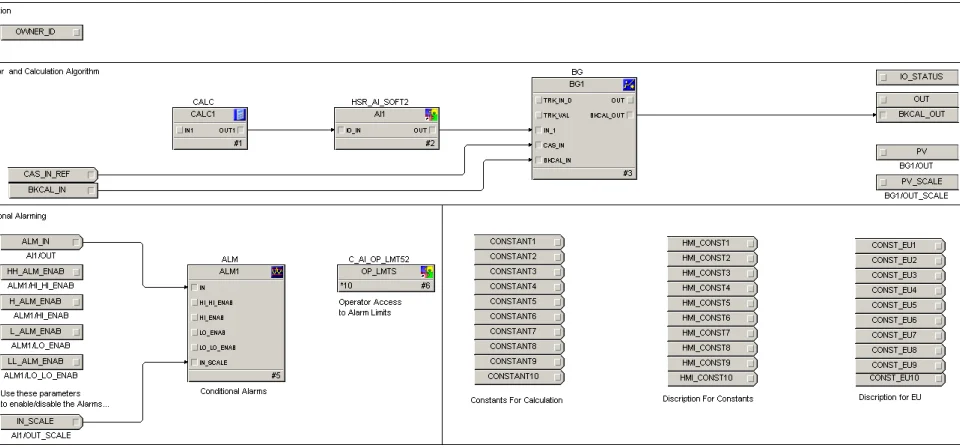

SCADA Software

New SCADA systems are true powerhouses; they can provide operators with a complete overview of their processes, enable remote control of the machinery, and allow advanced data processing. When SCADA first came to the scene in the 1970s, these advanced functions were minimal or non-existent.

Technological innovations are becoming increasingly prominent, faster, leaner, and more efficient, leaving the old SCADA systems stuck in the late 90s. Since that time, the internet has earned a central role in today’s businesses and society; smartphones, cloud software, and remote devices have changed how we socialize and conduct business every day.

The 21st century needs SCADA systems built with the internet, mobility, and remote access in mind. Some critical issues with outdated SCADA include:

- Old SCADA makes uploading problematic. Issues with speed, connectivity, and a lack of remote access introduce many risks and inconveniences.

- Old SCADA is glitchy and unreliable. Old SCADA often comes with bugs and glitches, making them unreliable and dangerous to your operations. Since they are phasing out and losing support, you cannot simply “patch” these issues and continue with business as usual.

- Old SCADA is platform dependent. Most outdated SCADA software runs on specific, proprietary operating systems (usually one by Microsoft), while new SCADA is platform independent.

- Old SCADA hinders you from becoming data driven. For instance, old SCADA limitsthe number of people and the amount of data you can add to your system while stifling collaboration and growth opportunities. New SCADA is limitless.

- Old SCADA is slow and inefficient. Outdated technology is slower and tedious; old SCADA systems are no different. They lack the high processing power of modern-day technology. From adding functionalities, implementing designs, and changing configurations, developing in old SCADA is near impossible.

- Old SCADA comes with security risks. Back in the 90s, the internet had just come out, and there were no smartphones. We did not have many of the security issues we have now. Along with this technological progression, it’s only natural that the architecture of SCADA would also change. Don’t be left in the dark ages with an old SCADA system.

Fortunately, like outdated PLCs, you can safely migrate your operations to a new SCADA

system.

At Crossroad Energy Solutions, we are the industry leaders in SCADA system migration and upgrades. Our expert technicians employ this process across North America, including in Calgary, Alberta. From the initial site inspection to an ongoing maintenance plan, we promise to protect your investment and manage the entire process for you.

Begin your organization’s transition into the digital age today. Contact us to learn more and to get started.