What is a PLC? What is a DCS? What is an RTU?

June 21, 2021

Obsolete HMI Hardware, Software, And SCADA Systems Migrations

July 21, 2021Obsolete PLC5 + SLC500 Migrations

Introduced by Allen-Bradley in 1986, the PLC5 was a game-changing innovation across countless industries; with as many as 450,000 platforms installed worldwide, it became an industry stalwart where its popularity was undisputed. Technology rapidly advances, however, and even good things come to an end. In June 2017, manufacturing of the PLC5 was discontinued and no longer receives support. In 1991, Allen-Bradley released the smaller and more efficient SLC500, which is also nearing obsolescence.

A sudden PLC failure requires a complex upgrade that touches upon multiple systems. The risks of not updating your system are significant and could cause serious damage to your company, equipment, and personnel. You wouldn’t run your business’ most critical applications on Windows 95—and using a 30-year-old technology should be viewed similarly.

The risks of not upgrading or migrating are serious, and include:

- Costly spare parts: PLC5 parts cannot be bought through Rockwell anymore so you are stuck using refurbished parts. Due to the shortage even used parts are very costly.

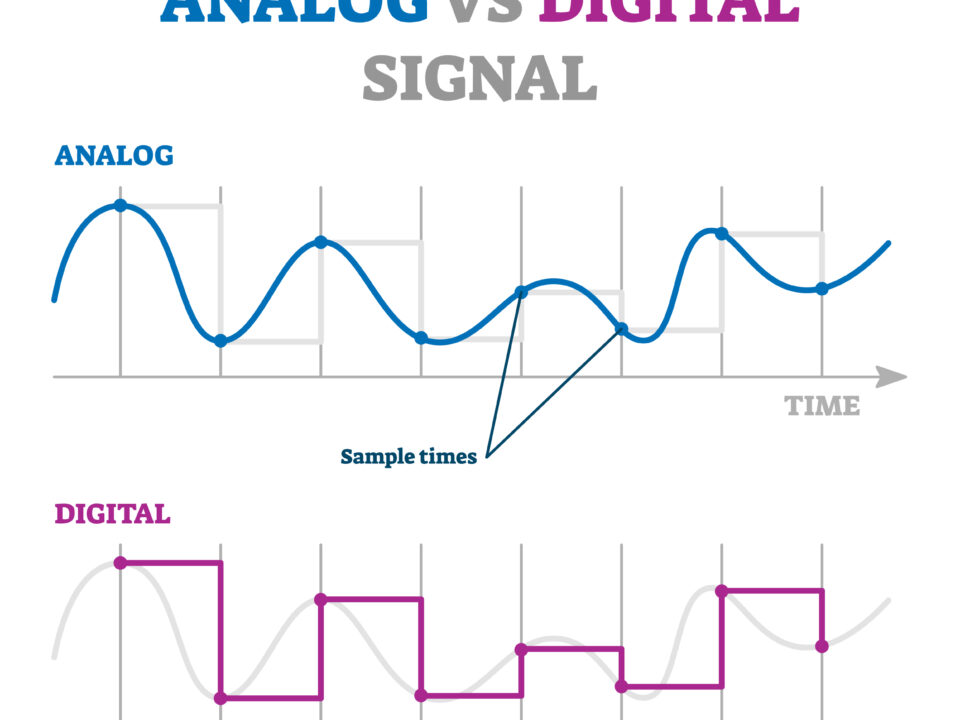

- Limited functionality: The newer PLC’s offer new communication protocols enabling integration with new devices.

- Other obsolesce: In addition to the PLC5 Controller, IO Cards and Communication Cards could be going obsolete. Control Net, for example, is nearing end of life.

- Extended outages: Risk to your business, people or environment due to a prolonged critical system failure.

Migration vs. Upgrade: Understanding the Difference

In simplified terms, an upgrade introduces an installation of new features and technologies. A migration, on the other hand, aims to keep things the same as much as possible. In fact, you might not even notice a difference. While a migration is considerably simpler and hassle-free, the downside is you’ll lose out on the productivity, safety, and efficiency that a full upgrade provides.

The Migration Process

At Crossroad Energy Solutions, we are industry leaders in system migration and upgrades. We handle this process across North America, including in Calgary, Alberta.

Here is the process we follow:

- A complete site assessment to evaluate existing hardware and site conditions.

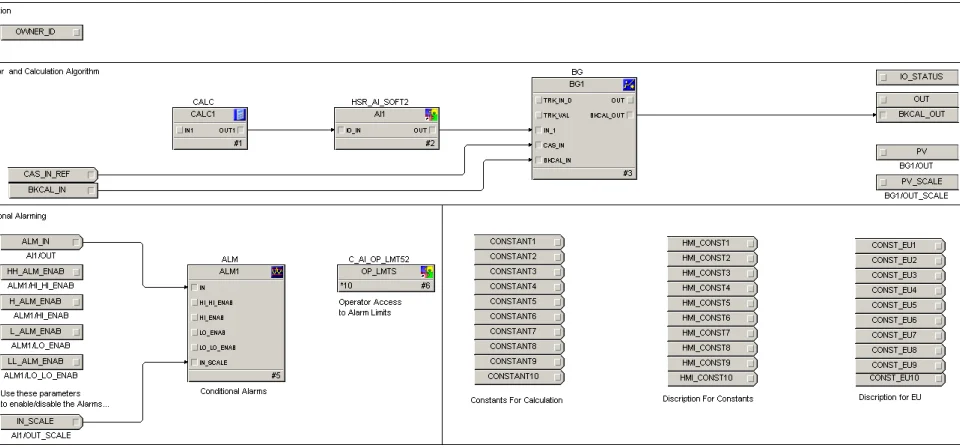

- An in-depth review of the existing program.

- Creation or update of cause-and-effect documentation and as-built electrical and P&ID drawings as required.

- Upgrade of source hardware to seamlessly run the new application.

- Migration or rewrite of the existing program to ensure it’s compatible with your upgraded PLC and site requirements.

- Modification of configurations to ancillary equipment that connect to the PLC so existing connections remain undisturbed.

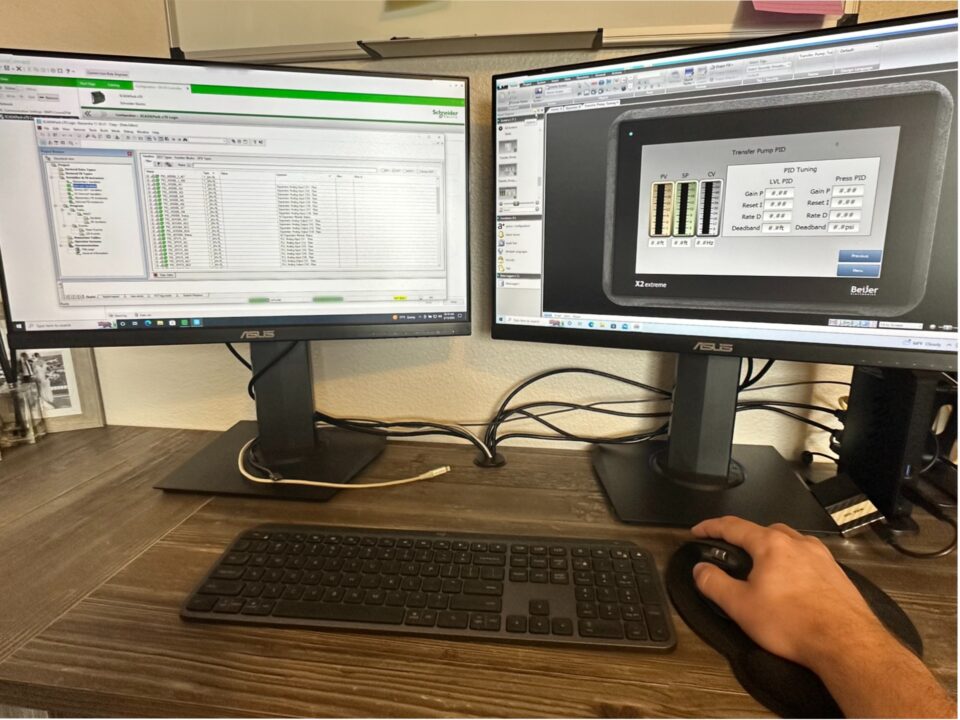

- Comprehensive Factory Acceptance Testing prior to bringing the new equipment to your site.

- Installation of the new equipment and commission during process outages.

- Creation of complete as-built drawings.

- Best-in-the-business follow-up and maintenance service.

The process of migrating or updating an old PLC to a new PLC can feel overwhelming. Our experienced team of industry leaders will help you decide the right move for your unique situation. Whether that entails a basic migration, a full upgrade, or a specially tailored hybrid approach, Crossroad Energy Solutions brings expertise and cutting-edge strategy to ensure you’re making the best choice. We will perform a full site audit of your existing technologies to determine which equipment would benefit most from modernization.

From the initial inspection to an ongoing maintenance plan, we promise to protect your investment and manage the entire process for you.

We pride ourselves on our cutting-edge technologies and expert technicians. We provide electrical, instrumentation, and automation services to the oil, gas, and industrial sectors nationwide. We are a people-focused company that encourages the personal and professional growth of all our employees.

Contact us today for a system lifecycle audit.