The End Of Venting Of Pneumatic Devices

August 9, 2021

Alternative Options For Pneumatic Venting

August 31, 2021Vent Testing And Inventorying Your Pneumatic Devices

As mentioned in our previous article, producers will need to substantially limit and control the venting of pneumatic devices & controllers or switch to other options such as instrument air, electrification, or venting capture.

Obviously, making these changes will come at a cost to producers. However, there are carbon credits available to help subsidize this transition.

A requirement to applying for carbon credits is getting a “baseline” measurement of a facility or producer’s starting emissions. This includes taking an equipment inventory as well as measuring or estimating the emissions associated with that equipment.

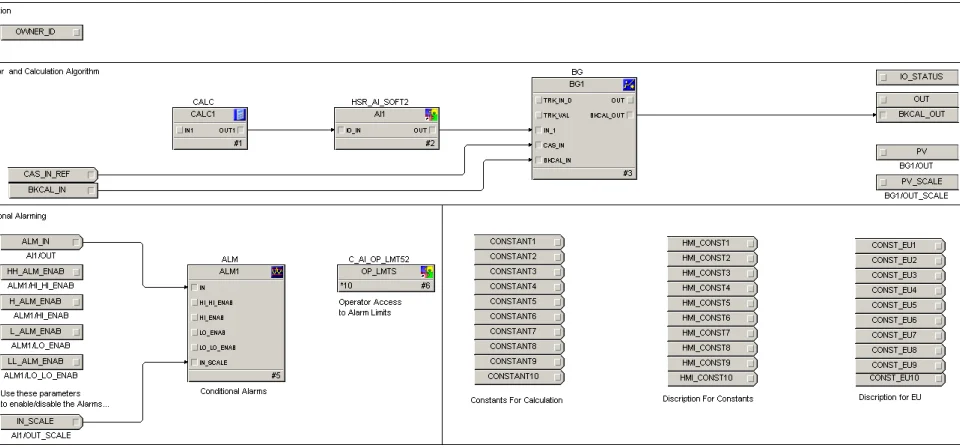

Crossroad Energy Solutions can handle this process for you. Information required and captured when taking field equipment inventories includes:

- Pneumatic device serial number or unique identifier

- Methane vent reduction index

- Project type

- Location

- Old device type

- New device type

- Old device sample vent rate

- New device sample vent rate

- Replacement date

- Decommissioning date

- Supply / signal pressure

- Injection pressure

Measuring vent rates is also an important part of establishing your baseline. Our technicians use a Positive Displacement Meter with auditable trending and will submit a report to you after the tests have been completed. This meter is highly accurate and reliable.

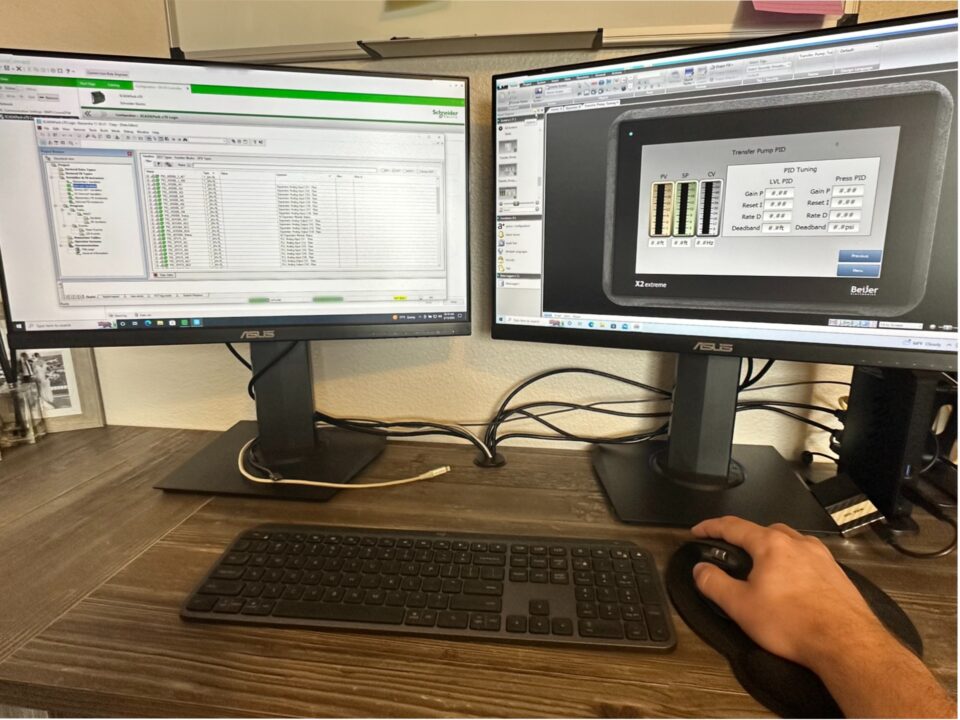

Crossroad Energy Solutions have trained technicians to take a physical count of which devices per site will need to be swapped out for something more efficient. In addition to this, we have test equipment that give accurate readings to record your device emissions to be used as a base line for how much your emissions reduce when equipment is upgraded. This is a critical step in earning carbon credits in the future.

Report and Suggest Upgrades on Non-compliant Equipment

Upon completion of site inventories & vent-gas testing, our technicians will submit a report with the findings and suggestions on how to become compliant.

The resulting upgrades and repairs may include:

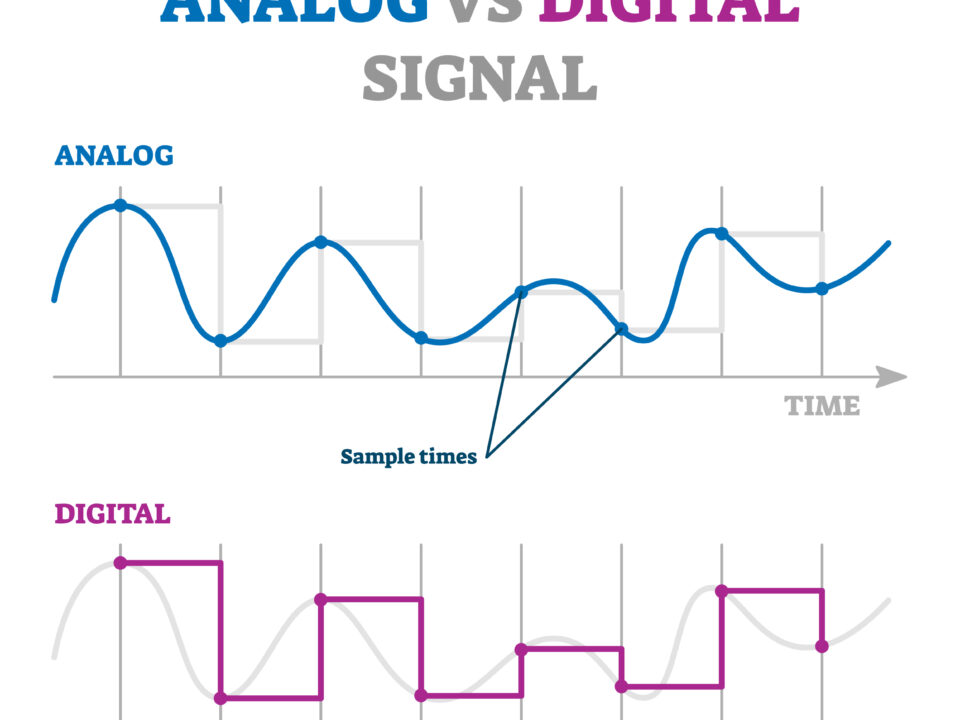

- Replacing pneumatic devices with electricity-powered pumps and controllers.

- Suggesting the installation of an instrument-air package (compressed air)

- Swapping out “high-bleed” pneumatic devices with intermittent (or “low bleed”) devices.

- Assessing current devices and repairing faulty equipment that releases improperly high emissions.

Checklist Overview

Ensure your compliance and actively reduce methane emissions from pneumatic devices:

- Keep an accurate inventory of all pneumatic device emissions.

- Repair or replace non-compliant pneumatic devices with electrically powered equipment wherever possible.

- Eliminate emissions from pneumatic devices by using compressed air and replace high-bleed gas-powered devices with low-bleed equipment.

- Follow a maintenance program to ensure continual compliance and annually report your pneumatic devices’ inventory.

Work with the Experts at Crossroad Energy Solutions

Protect your investment by avoiding government penalties—including the suspension of your production license—and start earning carbon credits.

Don’t wait — call our trusted industry experts at 877-872-0222 to schedule your assessment.