Vent Testing And Inventorying Your Pneumatic Devices

August 18, 2021

What Is SCADA, And Where Is It Used?

September 17, 2021In our previous two articles, we discussed changes within the regulatory framework governing pneumatic devices and controllers. Using the Alberta Energy Regulator’s Directive 60, section 8 as the industry standard, the venting of methane by pneumatic devices and controllers must be prevented, controlled, or significantly reduced in the case of some exemptions.

There are essentially four alternatives to controlling processes with methane emitting pneumatic devices, and they are as follows:

- Electrification

- Instrument air packages

- Capture

- Low-bleed devices

The right solution will depend on the unique situation of the equipment/site that you are upgrading. Below, we have laid out some key considerations to review before deciding to go ahead with a capital investment:

Converting from Pneumatic to Electric Instrumentation

Swapping out your pneumatically controlled devices for electric devices is a great option. This reduces all methane venting of the device, eliminates freezing issues, and also allows data trending to better track actuation.

A few questions you’ll need to answer are:

Is there a stable source of electricity on-site?

Line power or a generator will work great.

If there isn’t a source of electricity on-site – have you considered solar?

Technology has come a long way with electric control devices which allows them to draw less electricity and makes solar power a great alternative. In remote or un-electrified areas, this can be your cheapest and best option available.

If there isn’t a source of electricity on-site – have you considered fuel cells?

Fuel cell technology is an excellent low-emission way to add some extra backup to your solar. Fuel cells use a chemical reaction to produce electricity from methanol. The emissions are very low, and it’s a proven technology used all over the world.

Do you have problems with freezing/instrument air freeze up?

Electrification eliminates instrument air freezing issues. Full stop.

What kind of control system is available to run the instrumentation?

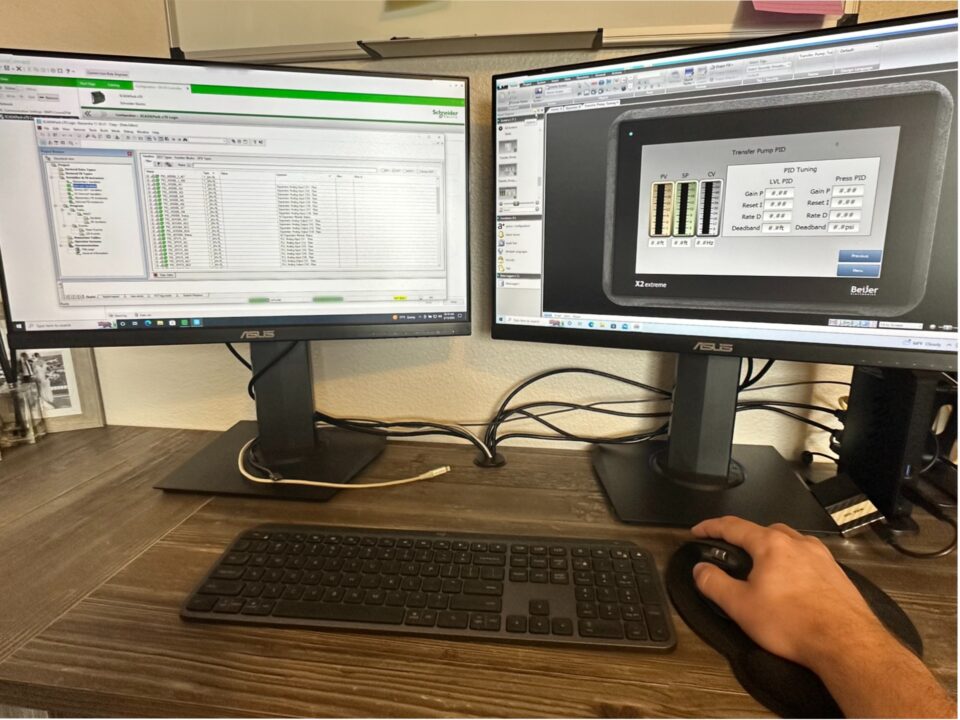

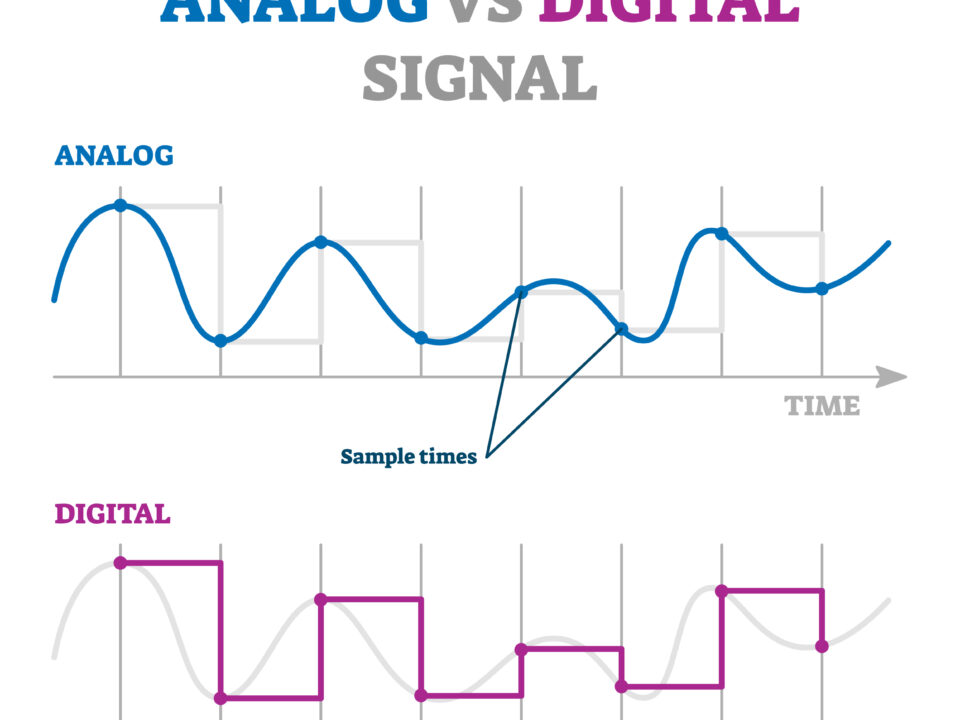

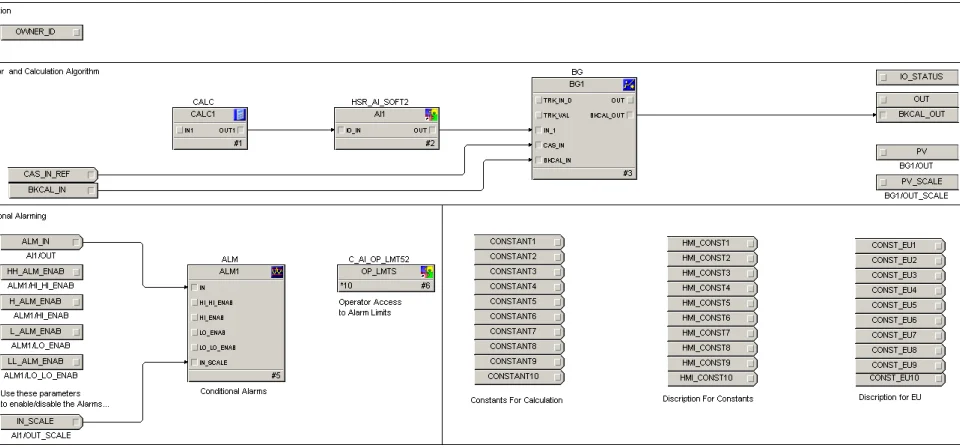

Electric valves need an electric signal to tell them to actuate. As a result, a control system needs to be installed in conjunction with the devices. This can be as simple as a level switch and a relay or as complex as a fully automated PLC/RTU that ties back into your existing SCADA system.

Can we use existing valve bodies and swap out actuators?

In most cases, installing electric devices doesn’t require touching the actual valve bodies. Down time is minimal and so is cost. However, if your valves are old and need replacement anyway, you’ll want to consider replacement in your budget.

What does the existing infrastructure look like?

Is this a new project? Old? Is there an existing tubing network that you can utilize for an instrument air package, or are you starting from scratch? This can be an important consideration when comparing the costs of electric devices to other options.

Instrument air packages

An instrument air package is a great option to get away from venting methane from your pneumatic devices. Essentially, this requires an air compressor, an air dryer, and sending compressed air to your pneumatic devices to facilitate actuation rather than methane gas.

A few things to consider before going with this option:

Is there a stable source of electricity on-site?

The air compressor will need a reliable source of electricity to power it. To avoid problems, this should either be a line-power or a generator power.

Does the tubing/piping infrastructure support instrument air, or are mods required?

Instrument air is a great option if there is already tubing/piping from the header to the instruments. If this isn’t already present, you’ll need to run tubing to every device, and this additional cost needs to be considered when figuring out your budget.

Do you have room for a compressor package on-site?

You need to consider that an instrument air package takes up space in any facility, and all locations are not created equal.

Compressed air can have trouble with freezing with cold temperatures.

Air compressors will need an air dryer to reduce the chance of freeze-ups. Air dryers are costly and require maintenance. Even with this measure in place, devices can still suffer from freezing issues.

Yearly Maintenance:

Air compressors, dryers, and generators all require maintenance to keep them running efficiently.

Capture:

Capture systems are designed to capture vented methane gas and combust them, either in an incinerator or as an alternative energy source in natural gas engines. There are some obvious benefits as it can help save fuel costs if the gas is used in engines.

How big is your site?

The cost of installing and building the tubing/piping infrastructure is often too high for small sites with a couple of pneumatic devices and pumps. Capture makes more sense for larger facilities, compressor stations, production tanks, and dehydration columns rather than an average upstream wellsite.

Low-bleed Devices

Greenfield – As of January 1st, 2022, no low-bleed devices will be allowed to be installed on new projects.

Brownfield – As of January 2023, retrofitting low-bleed devices will still remain an option on devices that were installed before January 1st, 2022. However, producers will need to tally and add the venting rates to OVG and DVG limits for their fields.

If you have any questions or clarifications, please reach out to our experts at Crossroad Energy Solutions. We service many areas across Canada and the USA, including Drayton Valley, AB.