Alternative Options For Pneumatic Venting

August 31, 2021

SCADA Migration Considerations

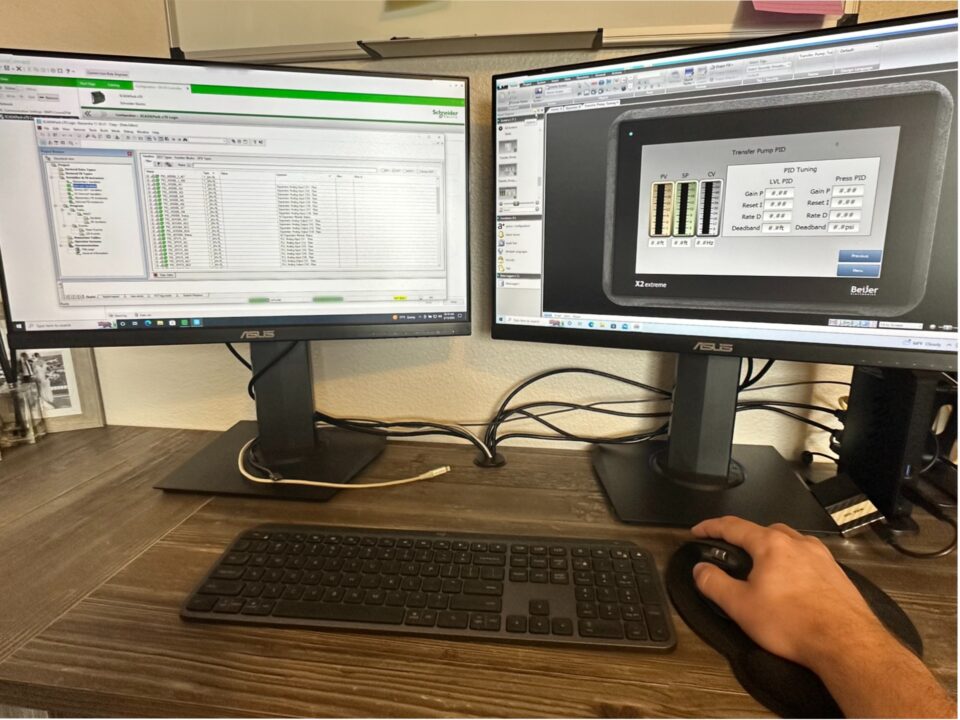

September 30, 2021Industrial facilities rely on absolute precision and coordination to effectively carry out operations. This is where 𝗦𝗖𝗔𝗗𝗔 (𝘀𝘂𝗽𝗲𝗿𝘃𝗶𝘀𝗼𝗿𝘆 𝗰𝗼𝗻𝘁𝗿𝗼𝗹 𝗮𝗻𝗱 𝗱𝗮𝘁𝗮 𝗮𝗰𝗾𝘂𝗶𝘀𝗶𝘁𝗶𝗼𝗻 𝘀𝘆𝘀𝘁𝗲𝗺𝘀) comes into the equation.

SCADA is a universally used system architecture found in modern-day industrial facilities worldwide. Composed of computers, networked data communications, hardware, and software components, SCADA provides industries with high-level supervisory management and processing power.

Simply put, SCADA systems are designed to monitor and control field devices at remote sites by collecting and processing real-time data.

This conveniently allows manufacturers to gather and analyze real-time production data from anywhere in the world. Furthermore, they can monitor and manage alarm systems and program important automatic control responses to protect their machinery.

The convenience and artificial intelligence (AI) SCADA offers creates a safer, more efficient, productive, and stable workplace.

Understanding the Value of SCADA

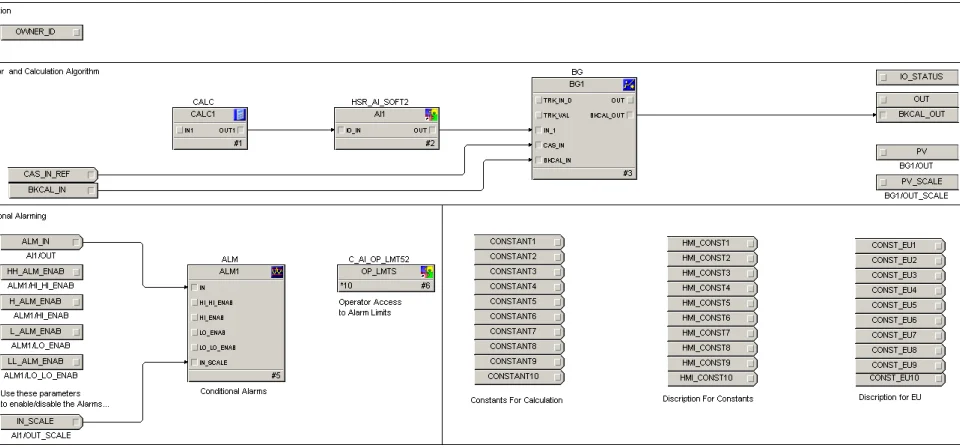

SCADA allows facilities and technicians to:

- Control industrial processes remotely or while onsite

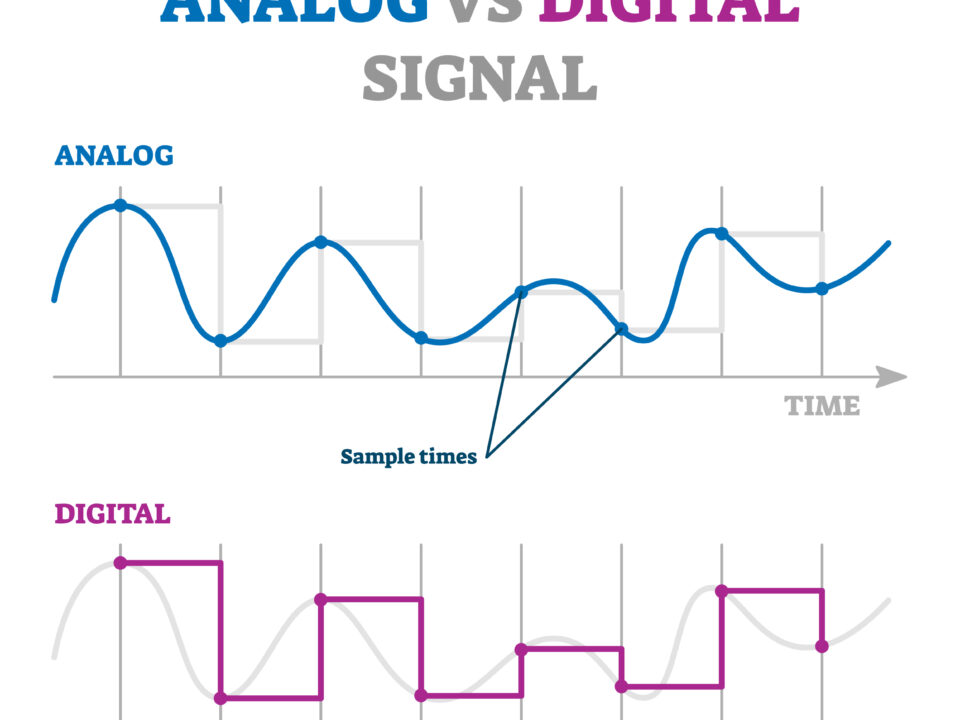

- Monitor, collect, and process real-time data

- Directly interact with important field devices such as valves, sensors, pumps, and motors through Human-machine Interface (HMI) software

- Record events into a log file

- Store performance data for analysis

- Proactively maintain equipment, thus decreasing downtime

- Provide important event and alarm notifications

The collection of this real-time data provides important insights, including:

- Maximizing operational and output efficiency

- Reducing overhead costs

- The ability to communicate and correct system issues to help mitigate downtime

- Streamlining overall performance

SCADA Systems also help bring awareness to potential network issues and allow technicians to make informed decisions based on the real-time data.

Relying on remote monitoring for the management and control of equipment eliminates human error, and further opens the doors to automate routine tasks that were once performed by technicians.

Who Uses SCADA?

Modern-day SCADA operates in a cloud environment, allowing complete remote control through tablets, computers, and smartphones. Here are various industries that depend on SCADA:

- Water Systems

- Wastewater Systems

- Oil and Gas Systems

- Electric Generation, Transmission and Distribution Systems

- Food Production Systems

- Pharmaceutical/Biotech

- Buildings, Facilities and Environments

- Manufacturing Plant Systems

- Mass Transit Systems

- Traffic Light Systems

Work with Our Industry Experts

SCADA systems are truly indispensable, and like any piece of technology, they are constantly upgrading and evolving. A well-developed SCADA system not only increases facility productivity and output, but minimizes any potential problems that could negatively impact your site or revenue stream.

Crossroad Energy Solutions is here to help. Call our team at 877-872-0222 to discuss your facility’s needs!