Crossroad Energy Solutions Is looking To Add New Technicians

February 4, 2022

What Is Modbus?

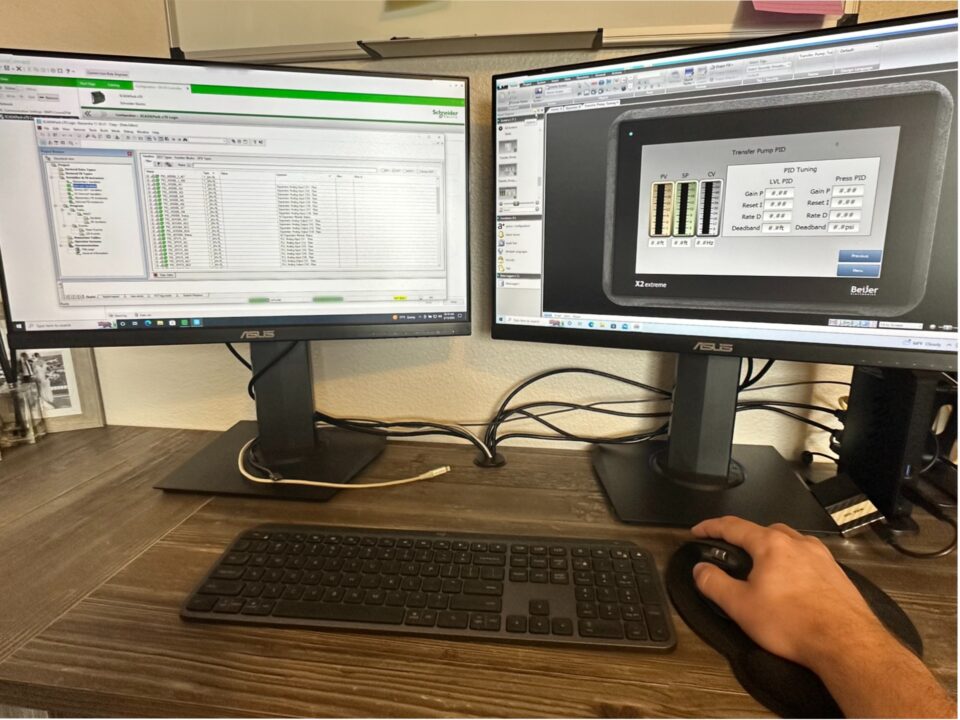

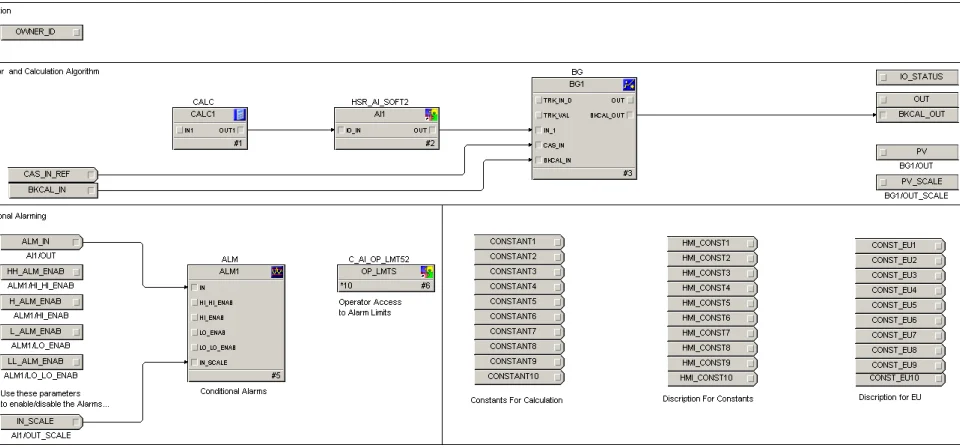

February 22, 2022Industrial communication protocols were developed to interconnect systems, interfaces and instruments that make up an industrial control system. Communication protocols are embedded within both software and hardware systems for industrial applications.

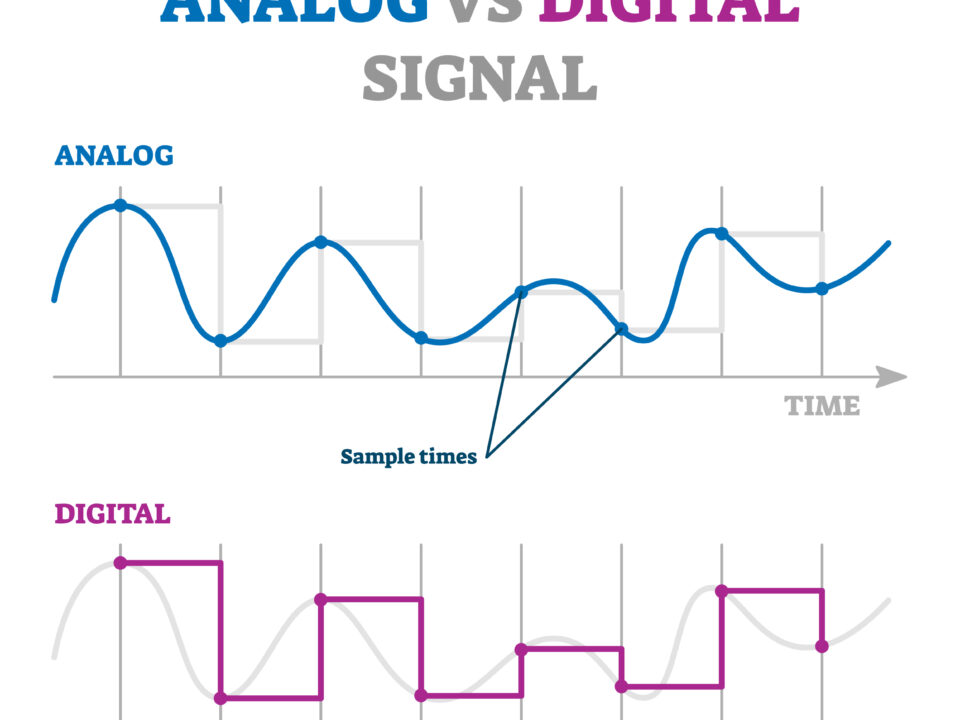

The main purpose of having these protocols in place is to facilitate the sending and receiving of information between software programs, devices, and control systems. Industrial communication protocols are necessary in both analog and digital communications.

Simply put, the communication protocols used in industrial control and automation systems allow communication between industrial devices and systems.

Let’s discuss more about industrial communication protocols below.

Types of Protocols

There are various types of communication protocols.

Some of these are:

- Ethernet/IP

- Modbus RTU

- Modbus TCP

- BACnet

- OPC UA

- DeviceNet

- ProfiBus

- ProfiNet

- EtherCat

- IO-Link

- CC-Link

- LonWorks

- CAN Open

- IEC 61131-3

- ASI-Interface

These communication protocols can either be proprietary or open to the public. Proprietary protocols are designed for use with specific networks or systems. Open protocols can be used by anybody.

Industries use a range of communication protocols that are made for specific needs. For instance, the Modbus protocol is considered a lightweight protocol for communication that provides basic read and write access by using the “Master/Slave” setup. Meanwhile, Ethernet/IP protocol uses Ethernet architecture to establish connection between automation devices for more robust requirements.

What’s at Stake

To maximize the usefulness of the latest technologies, companies should strive for seamless interoperability and connectivity between their systems. Selecting the right communication protocol is necessary as they ensure smooth end-to-end communications and avoids communication issues. Smoother the end-to-end communications creates more useful data, better supervision of the facility, more reliable control systems and more informed decision making.