What Is Communication Protocol In Industrial Control And Automation?

February 14, 2022

The Shortage Of Junior-Level Industrial Automation Technicians In Oil & Gas

March 9, 2022What Is Modbus?

If there’s a popular industrial protocol used today, Modbus could rank at the top of the list for many industries, and for good reason. It remains one of the most cost-effective, direct, yet easy-to-use standards that facilities have been using for many decades.

In fact, nearly all reputable industrial automation and instrumentation equipment providers support Modbus with the new products they release.

So what is Modbus and why is it so well-loved by many?

What is Modbus?

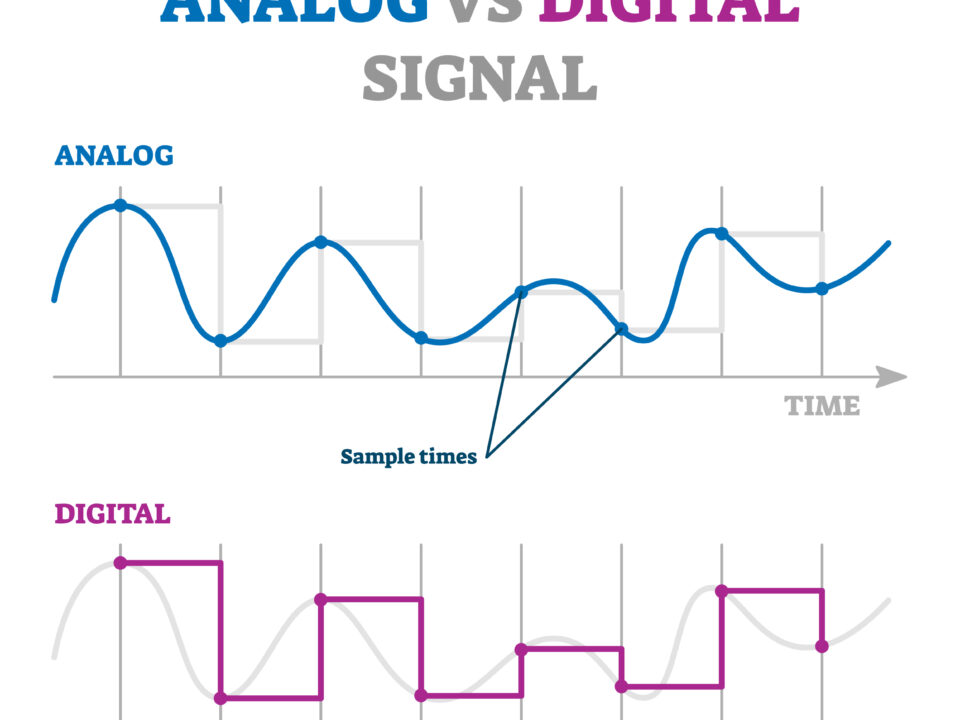

Modbus is an industrial protocol made by Schneider Electric (formerly Modicon) back in 1979 as a way for industrial devices to communicate through just one pair of wires. It originally operated over the RS232 scheme but was eventually adapted to work on the newer RS485. This move made it the default standard in industrial automation and it eventually was released as a royalty-free protocol for anyone to use.

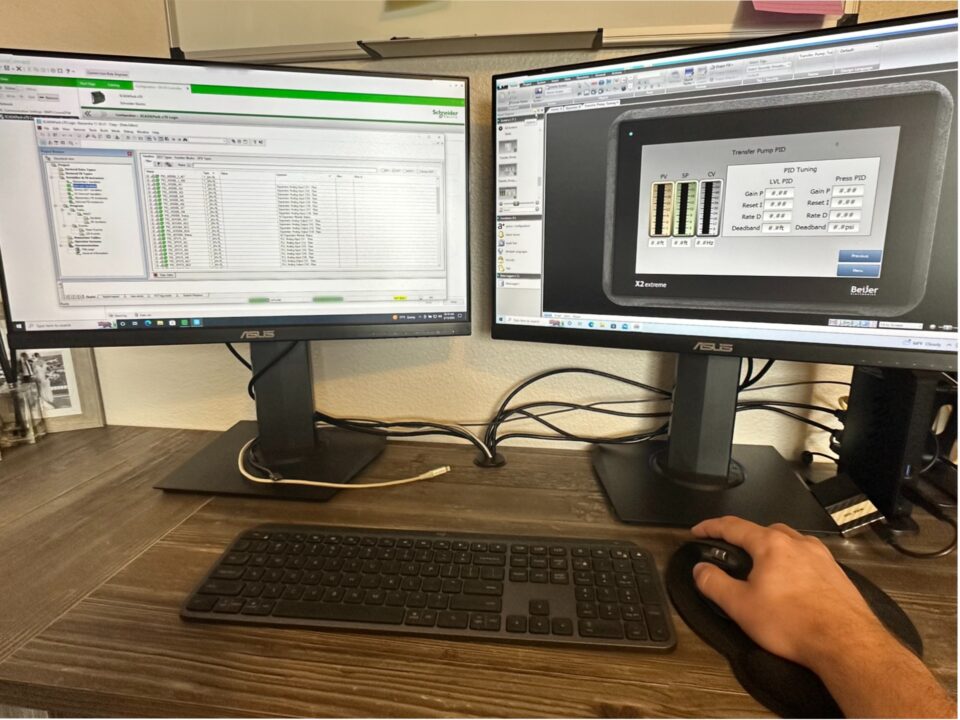

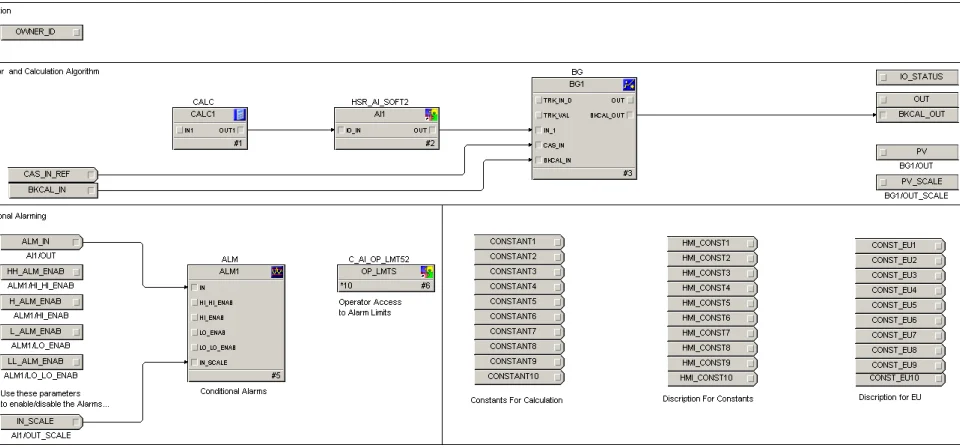

One can consider the Modbus as a “master-slave” system since it is capable of communicating with several “slaves” at once. Normally, the master most facilities use are either a distributed control system (DCS), programmable logic controller (PLC), or remote terminal unit (RTU).

The Modbus communication protocol has flourished throughout the past years because of its positive effects on the industrial automation and control industries. It being an open standard while using a simple approach has made it the best protocol for use by many organizations.

Where is Modbus Used?

Since Modbus is an open protocol, this means that manufacturers are free to use it in their equipment and don’t need to pay any fee to do so. Since it has become the standard protocol for communications in industry use, Modbus has become quite prevalent in connecting industrial devices together with existing systems.

The industry protocol is mainly used by manufacturers in various industries to transmit signals via their control devices and instrumentation. They then send the results back to a primary controller, which then forwards this information to a designated computer.

Manufacturers often use Modbus to link their supervisory computer with their own remote terminal unit or RTU. These are, in turn, connected to supervisory control and data acquisition systems, also known as SCADA.

There are also Modbus versions that are compatible with serial lines such as Modbus ASCII and Modbus RTU as well as Ethernet or Modbus TCP.

Why is Modbus Important?

Given that Modbus is mainly used as an industry communication protocol, its use as part of Industrial IoT or IIoT is inevitable. There are many systems today that use the Modbus protocol which plays a huge role in ensuring internet connectivity for facilities operating in industrial automation and control.

When an IoT device is connected to a Modbus protocol and its appropriate platform, it provides users with a secure duplex channel that they can use on the internet. Such connection allows facilities to bypass the need of using complex networks like firewalls and VPNs.

Additionally, the impact that the Modbus protocol has in the automation and control industries has significantly improved the performance, efficiency, connectivity, and robustness of companies here. These benefits have led to less time and cost needed to increase overall manufacturing productivity.