Electrical Maintenance – Three Critical Tasks & Other Considerations

November 26, 2021

Partners For Life With Canadian Blood Services

December 17, 2021Electronic Flow Meter Calibrations

Electronic Flow Meters (EFM) play an important role in industrial control settings. They measure liquid and gas flow rates and are suitable for industrial liquids like water, produced water, oil, natural gas, chemicals and a multitude of other gases and liquids not mentioned here.

There are a wide variety of different EFMs available and depending on the application, you could run into any of these in your facility. This is certainly not a comprehensive list of all EFM’s, but these are the most common ones you’ll find in your facility.

Differential Flow Meters – These meters function based on “Bernoulli’s Theorem” which states that flow rates can be calculated based on the square root of the differential pressure.

Vortex Flow Meters – These include an obstacle in the flow stream which disrupts the flow and creates vortices to form downstream of the obstacle. The frequency in which the vortices are formed is directly proportional to the fluid velocity.

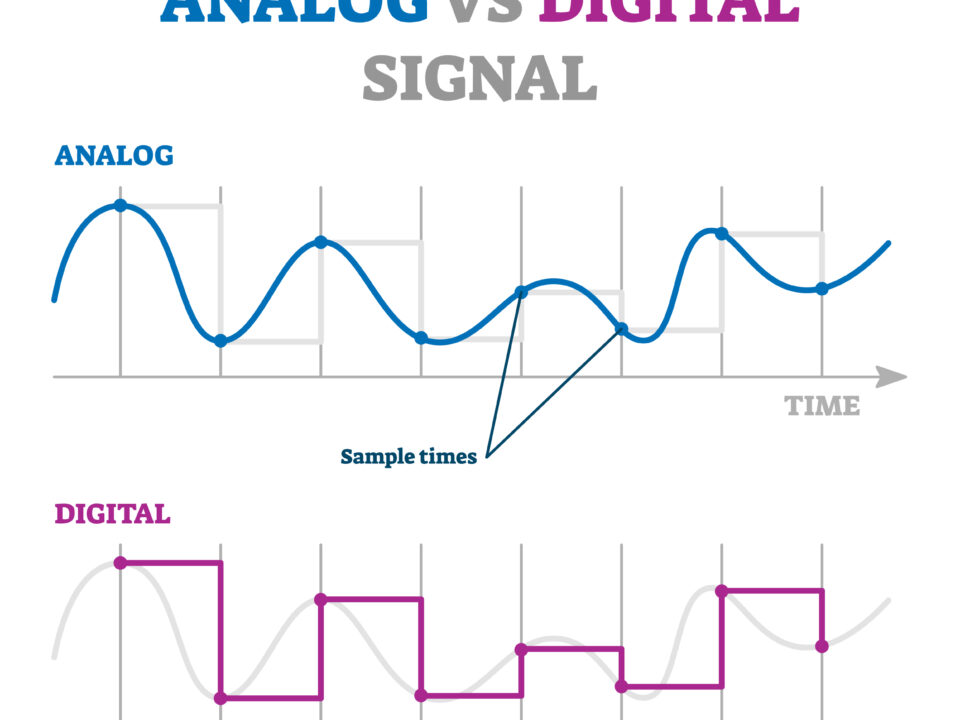

Electromagnetic Flow Meters – All things being constant, voltage induction by a conductive liquid across a magnetic field can be used to calculate flow rates

Turbine Flow Meters – These meters house a turbine that rotate as the fluid or gas pushes through it. By measuring rotation, you can determine flow rates

Ultrasonic Flow Meters – Transducers are used to send ultrasonic waves through the fluid or gas and back again. How the signal interacts with the substance indicates flow rates.

Positive Displacement Flow Meters – Known for being highly accurate, PD meters us mechanical cogs that move when fluid or gas flows through them. The movement is measured which creates an electrical signal and indicates flow rate.

Coriolis Flow Meters – Based on the principles of motion mechanics, Coriolis meters split the flow of fluid or gas into 2 tubes. These tubes are then intentionally oscillated which creates an electrical sine wave which can be measured and translated in flow rate.

Calibration:

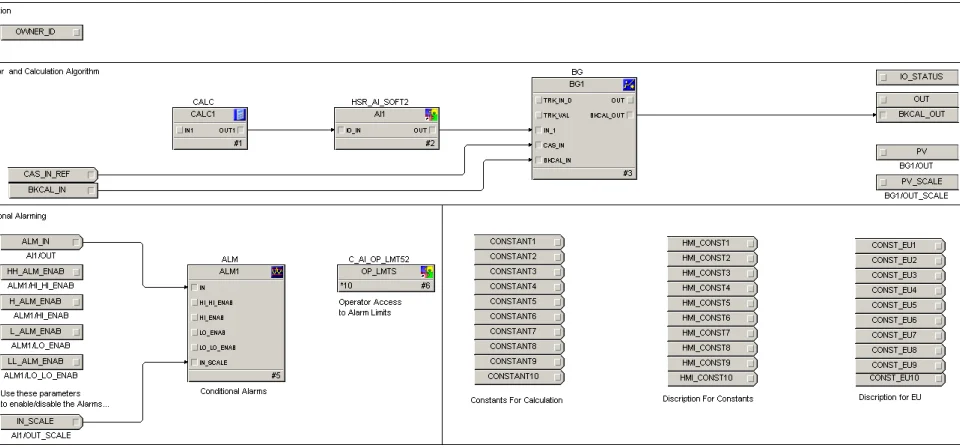

To ensure that your EFM is accurately measuring the flow rate of your fluids or gases, they need to be calibrated by a certified technician. For each EFM listed above, the calibration process will look a little different. However, what remains constant across all EFMs is the need for the readings of the instrument to be true and accurate so that volumes can be trusted.

Whether your EFM is measuring your fluid as a sales volume, as a chemical mixture volume or trying to figure out how much gas your well is producing, having an accurate reading is the most important function of an EFM.

Calibration is a small and necessary cost in comparison to what problems inaccurate readings could lead to. Lost revenues and inaccurate reporting are a few of the problems that can arise with measurement errors. To ensure your measurement remains accurate, we recommend having your EFMs calibrated on a regular basis following the manufacture’s recommendations and local regulatory requirements.

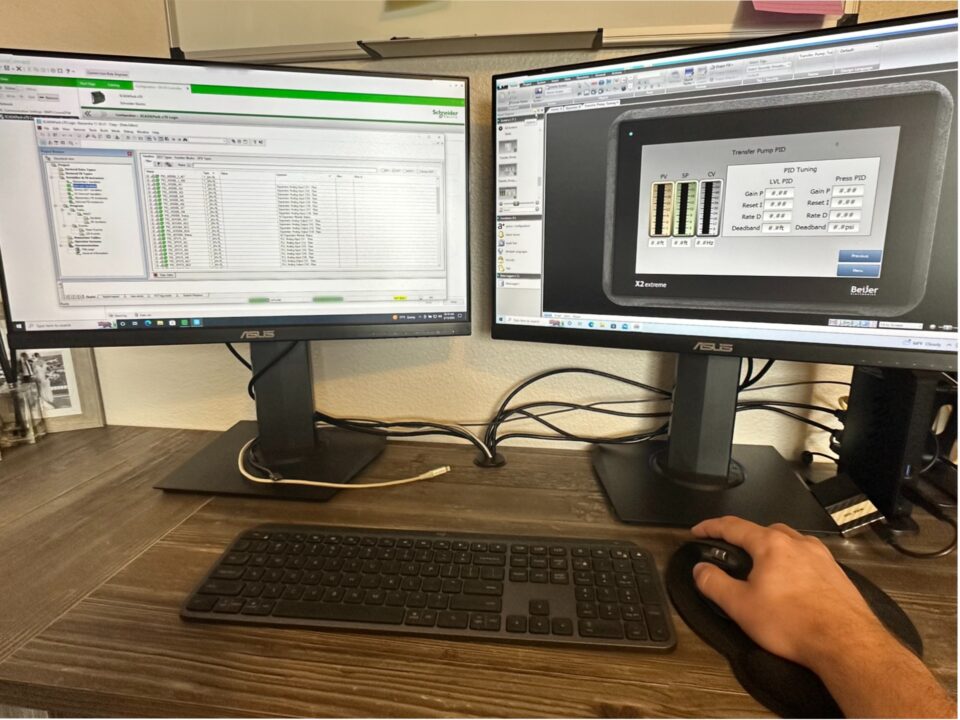

Crossroad Energy Solutions

Crossroad Energy Solutions offers instrumentation shop & field calibration services. During field calibrations, our technicians will inspect the orifice plate and/or meter element, update gas compositions, and complete all documentation and tagging/reporting to meet your company’s and local regulatory requirements.

Our areas of operations are as follows:

Shaunavon, Saskatchewan

Kindersley, Saskatchewan

Slave Lake, Alberta

Edmonton, Alberta

Drayton Valley, Alberta

Sylvan Lake, Alberta

Calgary, Alberta

Claresholm, Alberta

Medicine Hat, Alberta

Williston, North Dakota

Oklahoma City, Oklahoma

San Antonio, Texas

Dallas, Texas

Synder, Texas

McAllen, Texas

Give us a call to book a meter calibration at your facility: 1-877-822-022